The Vibrating Wire Concrete Stress Cell measures radial and tangential stresses in shotcrete, concrete and rock, usually in tunnel linings. The cells consist of two rectangular steel plates welded together around the periphery with a de-aired fluid occupying the space between the plates. A short tube connects the cell to a vibrating wire pressure transducer. The narrow gap between the plates is filled with hydraulic oil. A prestressing tube is provided for expanding the cell after the concrete has cured.A Vibrating Wire Pressure Transducer is connected to the cell by a short length of steel tubing, forming a closed hydraulic system.

Applications

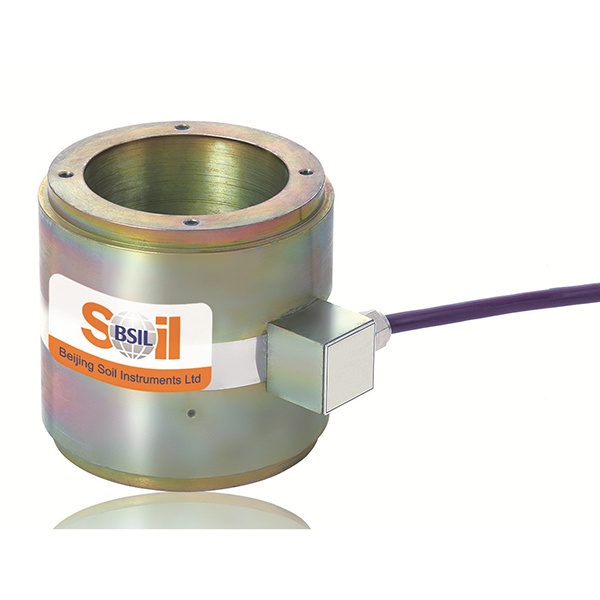

The Model BSIL-P10 NATM Style Shotcrete Stress Cell is designed for the measurement of tangential and radial stresses in shotcrete tunnel linings. Cells of this type are also used for measurements of stress in mass concrete.

Description

The Vibrating Wire Concrete Stress Cell measures radial and tangential stresses in shotcrete, concrete and rock, usually in tunnel linings. The cells consist of two rectangular steel plates welded together around the periphery with a de-aired fluid occupying the space between the plates. A short tube connects the cell to a vibrating wire pressure transducer. The narrow gap between the plates is filled with hydraulic oil. A prestressing tube is provided for expanding the cell after the concrete has cured.A Vibrating Wire Pressure Transducer is connected to the cell by a short length of steel tubing, forming a closed hydraulic system.