Applications

BSIL-C12 series IPI systems are used to measure lateral movement in the ground or in a structure. They are useful for determining the depth, direction, magnitude, and also rate of movement and can be used to ascertain the stability of retaining walls by measuring bending and rotation. Inclinometer systems can also be used to detect movement in the downstream and upstream side of dams and to define shear zones in the foundations of concrete faced dams.

Typical applications include: detecting slopes and landslides, determining shear and slip zones, monitoring diaphragm or sheet pile walls, monitoring bending in piles, verifying design assumptions and finite element analysis, horizontal IPI systems to measure settlement and deformation of concrete slabs and tank bases.

Description

The Model BSIL-C12A MEMS Vertical In-Place Inclinometers consist of a string of MEMS (Micro-Electro-Mechanical Systems) tilt sensors (uniaxial or biaxial) mounted on lengths of stainless steel tubing which are linked together by universal joints. The string of sensors is inserted inside a pipe, or a casing installed in a borehole in the ground, with the sensor cable(s) passing to the surface where they are connected to readout or dataloggers.

The Model BSIL-C12B MEMS Horizontal In-Place Inclinometer consists of a string of MEMS tilt sensors (uniaxial) mounted on lengths of stainless steel tubing which are linked together by

universal joints.

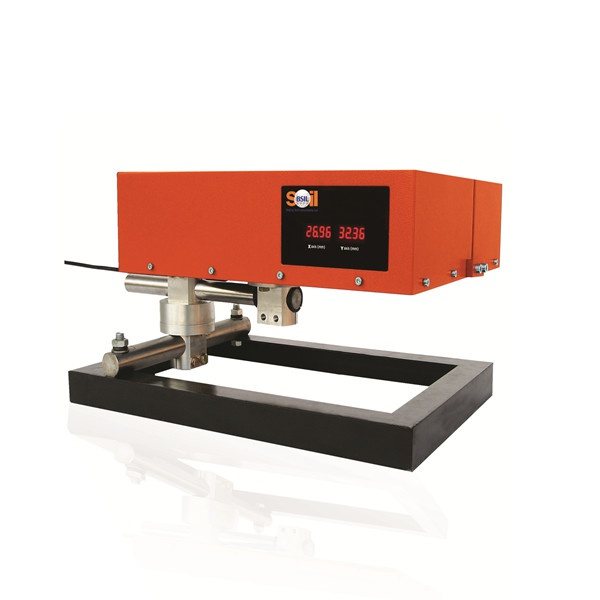

The Model BSIL-C12D Smart In-Place Inclinometer system(uniaxial or biaxial) is used to remotely monitor lateral displacement within a vertical borehole. The Smart IPI system comprises a data acquisition system, a Sensor Interface Module, one single cable can be connected with up to 40 Smart IPI nodes.

Key Features

◆Accurate and precise measurements using MEMS sensors

◆Robust design and reliable

◆Fit for manual or remote reading

◆Available in uniaxial and biaxial versions

◆In-built temperature compensation

Main Specifications

Model : BSIL-C12A | BSIL-C12B | BSIL-C12D

Range : ±15°(Vertical) ±15°(Horizontal) ±15°(Vertical)

Resolution :<10 arc seconds

Accuracy: ±0.1% F.S.

Operating Temperature: -20 to + 80°C

Sensor Output :±4V@±15°

Input Voltage :12 VDC

Minimum casing

internal diameter :56mm

Dimensions :Φ32mm x215mm

Operation

The tilt sensors are installed in inclinometer casing within a borehole, a sprung wheel assembly on the IPI engages into the keyways of the inclinometer casing to ensure alignment. Multiple IPIs are installed at varying depths and secured using gauge rods connected to the next and previous IPI.

The final gauge rod is secured at the top of the borehole using a top support assembly. Each IPI is connected to a datalogger which powers the sensors, initiates readings and retrieves the data.

Each tilt sensor also contains a thermistor to permit temperatures to be recorded.

The smart IPI sensors are connected to each other by means of a four-wire bus cable. Each sensor has a length of this cable exiting from the top and bottom of the sensor housing. The same cable (customer specified length) connects the uppermost sensor to the chosen readout (PC or datalogger, system, etc.).